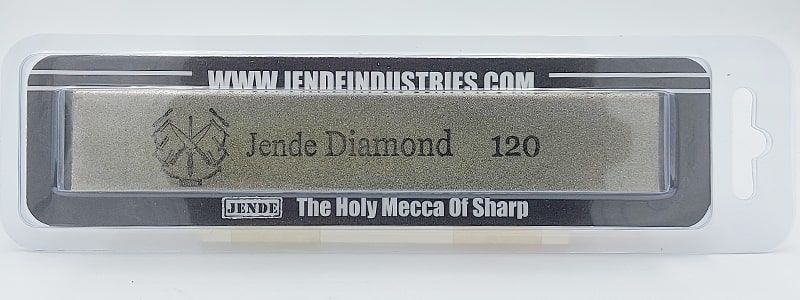

1x6 Jende 120 Grit Diamond Sharpening Stone Plate

- High quality Electroplated Diamonds

- 120 Grit is extra coarse and very aggressive

- Abrades all steel types, including ceramic

- Fits Jende JIGS, Edge Pro, Hapstone & TSProf sharpeners

The 1x6 Jende 120 Diamond Stone is an aggressive, extra coarse diamond plate used for serious profiling, repairs, and initial sharpening. Diamond abrasives at this level stay flat their entire lifespan, and don’t shed abrasive or hog water. They cut very quickly and efficiently, and are the best all-around replacements for the coarsest synthetic and natural stones. It works best when used in conjunction with the 300, 600 and 1200 grit plates.

This diamond plate is a premium extra coarse grit sharpening stone at a mid-range price. It works on all types of knives, scissors, tools and chisels. It particularly excels on those made with abrasion resistant steels and ceramic. The 1x6 size is meant for use with the Jende JIGS for Knives, Edge Pro, Hapstone and TSProf sharpeners. It is also a great size for a slip stone, field stone or a pocket stone for knife repairs and sharpening on the go.

1" x 6" x 5mm in size and mounted to a steel blank, this stone works best with water. It can also be used dry or with oil. Clean or rinse after use, and store in a dry place in between use to prevent any oxidation on the metal matrix.

Hacks and Tips:

-- Keeping the stone clean and hydrated with water will keep it more aggressive.

-- Change scratch directions as you sharpen to keep the stone from bottoming out.

| Description | The 1x6 Jende 120 Diamond Stone is an aggressive, extra coarse diamond plate used for serious profiling, repairs, and initial sharpening. Diamond abrasives at this level stay flat their entire lifespan, and don’t shed abrasive or hog water. They cut very quickly and efficiently, and are the best all-around replacements for the coarsest synthetic and natural stones. It works best when used in conjunction with the 300, 600 and 1200 grit plates. This diamond plate is a premium extra coarse grit sharpening stone at a mid-range price. It works on all types of knives, scissors, tools and chisels. It particularly excels on those made with abrasion resistant steels and ceramic. The 1x6 size is meant for use with the Jende JIGS for Knives, Edge Pro, Hapstone and TSProf sharpeners. It is also a great size for a slip stone, field stone or a pocket stone for knife repairs and sharpening on the go. 1" x 6" x 5mm in size and mounted to a steel blank, this stone works best with water. It can also be used dry or with oil. Clean or rinse after use, and store in a dry place in between use to prevent any oxidation on the metal matrix. Hacks and Tips: |

|---|---|

| Width | 6 |

| Length | 1 |