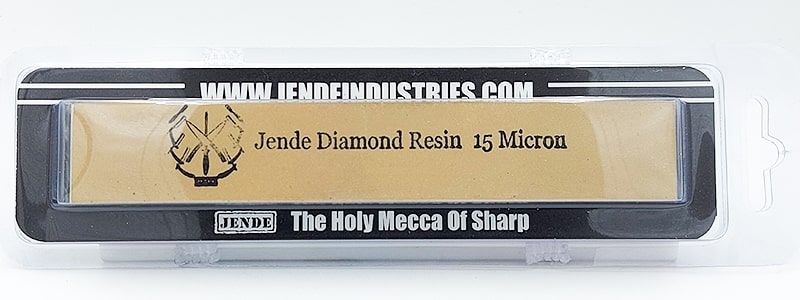

1x6 Diamond Resin Stone 15 Micron

- The 15 micron diamond resin stone is splash and go and meant to be used with water

- Best used after a coarser diamond plate or stone, and really sets the stage for an amazing mirror finish when followed by the finer 9, 6, and 3 micron resin diamond stones.

- For routine sharpening and maintenance.

- Can be used to establish a working sharp edge, for cleaning up scratches from coarser diamond plates

- The 15 Micron 1x6 Jende Diamond Resin Stone is equivalent to 1,000 grit

The 15 Micron 1x6 Jende Diamond Resin Stone is equivalent to 1,000 grit, and can be used to establish a working sharp edge, for cleaning up scratches from coarser diamond plates, and for routine sharpening and maintenance. This stone is best used after a coarser diamond plate or stone, and really sets the stage for an amazing mirror finish when followed by the finer 9, 6, and 3 micron resin diamond stones.

The Jende Resin Diamond Plates are designed to be used as part of an all-diamond lineup that has a longer lifespan than the already wide ranging 10 grits of Jende Diamond Films. This long-life lineup includes the Jende 1x6 Diamond Plates in 120, 300, 600 and 1200 grit, then the 1x6 Diamond Resin Stones in 15, 9, 6, and 3 micron, followed by Jende Poly Diamond Stropping Emulsions with the Jende Leather, kangaroo and nanocloth strops.

The 15 micron diamond resin stone is splash and go and meant to be used with water. Let it air dry between use. Size is 1" x 6" x 5mm in size and mounted to a stainless steel blank. Even though the 1x6 size is meant for use with the Jende JIGS for Knives, Edge Pro, Hapstone and TSProf sharpeners, it is also a great size for a slip stone, field stone or a pocket stone for knife sharpening on the go, or to remove unwanted burrs.

Abrasive: Diamond

Ideal place in a sharpening progression:

-- Starting grit for following a factory angle edge and for lighter profiling.

-- Starting grit for light repair and maintenance of an already sharpened but dull edge.

-- After any diamond grit plate or stone to remove the deeper diamond scratches.

-- After lower grit sharpening stones (120, 220, 320, 400, 600, 800 grit)

-- After coarse belt grinder grits (60, 80, 100, 120, 220 grit)

-- Before progressing to a finer and/or upper medium grit stone (1,200 - 6K grit)

-- A final stone for basic sharpness on many knives and tools.

On More Traditional Carbon Steel and Stainless Steel Edges, the 15 micron diamond resin stone works on all steels and ceramics. On softer end stainless steels used by many kitchen knife makers like Henckels, Wüsthof, Gunter Wilhelm, F Dick, Victorinox, etc. such as X50CrMoV15, AUS6, 440B, this 15 micron stone leaves a clean looking edge that is suitable for most cutting tasks .

On these steel types, this stone can maintain a serviceable edge, but does require a lower grit stone for any real damage or change in profile.

On the higher end of the hardness spectrum of traditional steel edges made with steels like 1095, 52100, 440C, Aogami White, Shirogami Blue, O1, W1, etc. The Jende diamond resin stones are amazing. The 15 micron diamond resin stone easily establishes a clean looking edge, removes earlier and deeper scratches, and sets the foundation for a clean mirror at higher grits. It can be used as a stand-alone stone to maintain the sharpness, but will require a coarser grit stone to do more serious repairs or profiling. The edges one these harder steel types do very well at the 15 micron level, but ar capable of so much more.

On Carbide Forming Steel and More Abrasion Resistant Steel Edges such as VG-10, D2, M2, S35V, S90V, etc., is exactly what the Jende 15 micron diamond resin stone was made for. Diamonds cut through everything with ease, including super hard carbides these steels are famous for. SInce the diamond cut through the matrix steel and the carbides equally, the overal finish off the Jende resin stones is consistent and more mirror like, while still having bite. The edge off this stone can be used as is, or to be further refined with stropping or finer grits stones.

Hacks and Tips:

-- Use a moderate amount of water when sharpening with this stone to avoid the black swarf buildup. A cleaner surface will cut faster than one with a lot of swarf.

-- If using this stone as a final or polishing grit, keep the black swarf viscous and it will produce a slightly more refined edge.

-- Lap this stone ONLY with a Jende 2-Sided Glass Lapping Plate and Silicon Carbiode powders. Lapping diamonds to diamond only wears the diamonds down, and doesn't revitalize the resin stones.

-- The Jende Diamond Resin stones can be used in conjunction with oil stones (such as Norton India and other carborundum and Arkansas stones) if the blade is wiped clean before and after switching stone types. They can also be used in a mix and match progression with other synthetic and natural sharpening stones, as well with other brands such as Shapton, Sigma, Suehiro, Imanishi, Spyderco, King, etc.

| Description | The 15 Micron 1x6 Jende Diamond Resin Stone is equivalent to 1,000 grit, and can be used to establish a working sharp edge, for cleaning up scratches from coarser diamond plates, and for routine sharpening and maintenance. This stone is best used after a coarser diamond plate or stone, and really sets the stage for an amazing mirror finish when followed by the finer 9, 6, and 3 micron resin diamond stones. The Jende Resin Diamond Plates are designed to be used as part of an all-diamond lineup that has a longer lifespan than the already wide ranging 10 grits of Jende Diamond Films. This long-life lineup includes the Jende 1x6 Diamond Plates in 120, 300, 600 and 1200 grit, then the 1x6 Diamond Resin Stones in 15, 9, 6, and 3 micron, followed by Jende Poly Diamond Stropping Emulsions with the Jende Leather, kangaroo and nanocloth strops.

-- Starting grit for following a factory angle edge and for lighter profiling. On More Traditional Carbon Steel and Stainless Steel Edges, the 15 micron diamond resin stone works on all steels and ceramics. On softer end stainless steels used by many kitchen knife makers like Henckels, Wüsthof, Gunter Wilhelm, F Dick, Victorinox, etc. such as X50CrMoV15, AUS6, 440B, this 15 micron stone leaves a clean looking edge that is suitable for most cutting tasks . On these steel types, this stone can maintain a serviceable edge, but does require a lower grit stone for any real damage or change in profile. On the higher end of the hardness spectrum of traditional steel edges made with steels like 1095, 52100, 440C, Aogami White, Shirogami Blue, O1, W1, etc. The Jende diamond resin stones are amazing. The 15 micron diamond resin stone easily establishes a clean looking edge, removes earlier and deeper scratches, and sets the foundation for a clean mirror at higher grits. It can be used as a stand-alone stone to maintain the sharpness, but will require a coarser grit stone to do more serious repairs or profiling. The edges one these harder steel types do very well at the 15 micron level, but ar capable of so much more. On Carbide Forming Steel and More Abrasion Resistant Steel Edges such as VG-10, D2, M2, S35V, S90V, etc., is exactly what the Jende 15 micron diamond resin stone was made for. Diamonds cut through everything with ease, including super hard carbides these steels are famous for. SInce the diamond cut through the matrix steel and the carbides equally, the overal finish off the Jende resin stones is consistent and more mirror like, while still having bite. The edge off this stone can be used as is, or to be further refined with stropping or finer grits stones. Hacks and Tips: -- Use a moderate amount of water when sharpening with this stone to avoid the black swarf buildup. A cleaner surface will cut faster than one with a lot of swarf. |

|---|---|

| Width | 1 |

| Length | 6 |