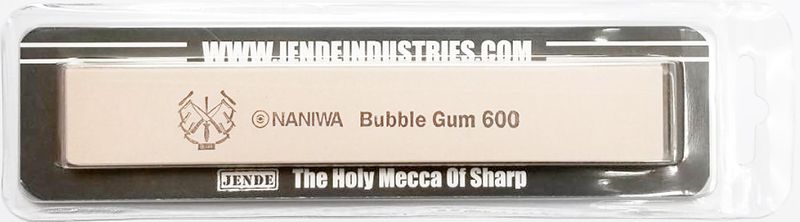

The 1x6" Naniwa 600 Grit "Bubble Gum" stone is a very flexible coarse stone used for profiling, repairs and initial maintenance on your edges. It gets its name from the bubble gum pink flavor, and has a smooth, soft feel to it that packs quite an aggressive punch. This stone cleans up deeper factory scratches, makes transitioning from diamond plates and stones easier and cleaner, and is a good foundation stone before progressing to finer grits.

Mounted to a blank and 1" x 6" x 5mm in size, this stone is used with water only and work best when soaked in water for a minute or two or until any bubbles stop before use. Store in a dry place in between use.

Abrasive Material: Aluminum Oxide

Ideal place in a sharpening progression:

The 600 Grit Naniwa Bubble Gum sharpening stone is a mid-range sharpening stone that works on almost all types of knives, scissors, tools and chisels, including those made with abrasion resistant steels. While the 1x6 size is meant for use with the Jende JIGS for Knives, Edge Pro Apex, Edge Pro Pro, Hapstone Sharpener, and TSProf Sharpeners, it is also a great size for a slip stone, field stone or a pocket stone for knife sharpening on the go, or to remove unwanted burrs.

On More Traditional Carbon Steel and Stainless Steel Edges the Naniwa 600 Bubble Gum works on steels between RC 52 and RC 65 on the Rockwell C Hardness scale. The stone is softer and quicker than other Naniwa stones, and will make a consistent matte finish on the softer end of the spectrum of steels like X50CrMoV15, AUS6, 440B, and most steels used by many kitchen knife makers like Henckels, Wüsthof, Gunter Wilhelm, F Dick, Victorinox, etc.

On the higher end of the hardness spectrum of traditional steel edges made with steels like 1095, 52100, 440C, Aogami White, Shirogami Blue, O1, W1, etc. The 600 Bubble Gum is incredible. The softer matrix of the stone makes cutting these steels like butter, and the finish it leaves is a light scratch pattern that is easily worked out on the next levels. While it can remove rust and reestablish bevels and edges, it is a really good second-step stone after belts or coarse grit stones.

On Carbide Forming Steel and More Abrasion Resistant Steel Edges such as VG-10, D2, M2, S35V, S90V, etc. The 600 Bubble Gum stone acts similarly to higher hardness carbon and stainless steels to be a very effective second-step cleanup stone. The softer matrix conforms with the edges and really evens out coarser stone, diamond plate, and belt sander scratches to prep the edge for a more even surface before going to finer grits.

Hacks and Tips:

Alternative Premium Level Stones: Shapton 500, Naniwa Chosera 600

| Description |

The 1x6" Naniwa 600 Grit "Bubble Gum" stone is a very flexible coarse stone used for profiling, repairs and initial maintenance on your edges. It gets its name from the bubble gum pink flavor, and has a smooth, soft feel to it that packs quite an aggressive punch. This stone cleans up deeper factory scratches, makes transitioning from diamond plates and stones easier and cleaner, and is a good foundation stone before progressing to finer grits. Mounted to a blank and 1" x 6" x 5mm in size, this stone is used with water only and work best when soaked in water for a minute or two or until any bubbles stop before use. Store in a dry place in between use. Ideal place in a sharpening progression:

The 600 Grit Naniwa Bubble Gum sharpening stone is a mid-range sharpening stone that works on almost all types of knives, scissors, tools and chisels, including those made with abrasion resistant steels. While the 1x6 size is meant for use with the Jende JIGS for Knives, Edge Pro Apex, Edge Pro Pro, Hapstone Sharpener, and TSProf Sharpeners, it is also a great size for a slip stone, field stone or a pocket stone for knife sharpening on the go, or to remove unwanted burrs. On More Traditional Carbon Steel and Stainless Steel Edges the Naniwa 600 Bubble Gum works on steels between RC 52 and RC 65 on the Rockwell C Hardness scale. The stone is softer and quicker than other Naniwa stones, and will make a consistent matte finish on the softer end of the spectrum of steels like X50CrMoV15, AUS6, 440B, and most steels used by many kitchen knife makers like Henckels, Wüsthof, Gunter Wilhelm, F Dick, Victorinox, etc. On the higher end of the hardness spectrum of traditional steel edges made with steels like 1095, 52100, 440C, Aogami White, Shirogami Blue, O1, W1, etc. The 600 Bubble Gum is incredible. The softer matrix of the stone makes cutting these steels like butter, and the finish it leaves is a light scratch pattern that is easily worked out on the next levels. While it can remove rust and reestablish bevels and edges, it is a really good second-step stone after belts or coarse grit stones. On Carbide Forming Steel and More Abrasion Resistant Steel Edges such as VG-10, D2, M2, S35V, S90V, etc. The 600 Bubble Gum stone acts similarly to higher hardness carbon and stainless steels to be a very effective second-step cleanup stone. The softer matrix conforms with the edges and really evens out coarser stone, diamond plate, and belt sander scratches to prep the edge for a more even surface before going to finer grits. Hacks and Tips:

Alternative Premium Level Stones: Shapton 500, Naniwa Chosera 600 |

|---|---|

| Width | 1 |

| Length | 6 |